What is the market potential for tile adhesive in India compared to its current volumes?

Tile Adhesive Business: Considering the total sales volumes of organized, semi-organized, and unorganized companies in the tile adhesive industry, it represents only a small fraction when compared to the estimated 400 million metric tons of cement demand in India. Quite a good amount of this huge volume also goes into the interiors of the house and a part of that is used for fixing tiles.

So, what does the traditional grey cement business have to do with tile adhesive?

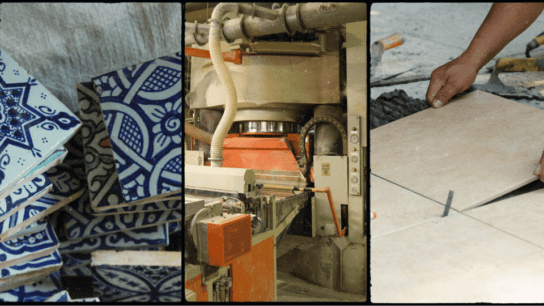

There is a significant need for customer education when it comes to using adhesive for tile installation. Fixing tiles with an adhesive and grout system requires skilled workmanship as a prerequisite. By improving the quality of tiling, ceramic tiles can truly deliver the expected results.

Let’s take a closer look. Roughly estimated, India’s annual tile production amounts to 800 million square meters. But the usage of tile adhesive is significantly lower compared to thick-set cement mortar used for tile installation. Lack of product awareness and a shortage of trained contractors and masons pose challenges.

Although we have seen a sudden spur and entry of traditional big cement and paint players (e.g. Ultratech, Asian Paints) into this business with impressive starting volumes and more impressive business plans, the market potential is huge, and I do not see any challenge in converting cement-mortar to tile -adhesive as far as individual house builder segment is concerned. In large projects, cost comparison and shortage of trained manpower are the real challenges.

Buy this Book: MODERN CERAMIC TILES: A Handbook for Professionals

Expert Opinion about Tile Adhesive Business

Building material expert Dinesh Vyas says – “In my opinion, the tile and adhesive industries should collaborate to educate customers, contractors, and consultants to enhance the overall value of tiling. Achieving economies of scale would help reduce overhead costs and provide cost savings for both customers and manufacturers.”

Read this Article also: Paints: Colour Dilemma to Quality Concerns, While Choosing Paints!

Even if just 50% of the usage of grey cement is replaced by tile adhesives in tiling projects, the impact can be significant. Moreover, cement doesn’t lose its market share; it simply transforms its form and packaging.

This can be a winning proposition for everyone involved, including end-users, architects, interior designers, contractors, tile manufacturers, and tile adhesive manufacturers. Ultimately, the biggest winners would be the end-users who invest in interiors and tiles, expecting satisfactory results.

Read this Article also: Tile Adhesive and Grouts | Untapped Potential in India